The rise of Industry 4.0 is driving manufacturers to adopt AI and machine learning. These powerful technologies help unlock valuable insights from data, empower businesses with smarter decision-making, and optimize operations. Did you know that 48% of businesses leverage some form of AI to extract value from big data? This blog will delve into the importance of AI-powered data management and how Informatica is your key to success.

Industry 4.0: The New Manufacturing Era is Here

Industry 4.0, also known as 4IR, represents the fourth major industrial revolution, characterized by the integration of advanced technologies like artificial intelligence, machine learning, and the Internet of Things into manufacturing processes. This creates a more automated, interconnected, and data-driven production environment.

Just a few years ago, Industry 4.0 was a niche term known only to a handful of tech enthusiasts. Fast forward to 2019, and it had become a top priority for manufacturers worldwide. 68% of respondents in a global McKinsey survey considered Industry 4.0 a cornerstone of their strategy, with 70% actively implementing new technologies to achieve it.

A Quick Breakdown of the Key Aspects of Industry 4.0

Smart Factories: Production facilities leverage intelligent systems and automation for tasks like monitoring equipment, optimizing production lines, and managing supply chains.

Real-Time Data & Analytics: Sensors and connected devices collect vast amounts of data, allowing for real-time insights and informed decision-making.

Advanced Automation: Autonomous vehicles, and other intelligent machines handle repetitive tasks, improving efficiency and safety.

Cloud-Based Manufacturing: Cloud computing offers scalability, flexibility, and access to advanced analytics tools for optimizing production processes.

How AI in Manufacturing Makes Sense

The manufacturing industry generates an estimated 1,812 petabytes of data annually. This explosion of digital information in recent years has created a challenge – how to effectively utilize this data to make informed decisions.

Here comes in AI! AI adoption is surging – Over 80% of companies now prioritize AI as a cornerstone of their business strategy. The value of AI in manufacturing is attracting major investments. Accenture predicts that AI will generate $3.78 trillion for manufacturing by 2035.

As per Deloitte survey, 83% of companies believe AI will deliver practical and noticeable benefits. 27% of companies have already witnessed value from their AI projects, with an additional 56% anticipating positive results within the next 2-5 years.

The Importance of AI in Data Management

Here’s a hypothetical scenario to help you understand this:

Let’s say there’s a manufacturing company that traditionally relies on manual data collection and analysis to monitor production lines and optimize processes. This approach results in a common problem – managing and making sense of the data generated across their production lines. The production schedules, quality control metrics, and equipment maintenance logs are scattered across disparate systems.

Benefits of AI-powered data management

With the implementation of AI-powered data management, the company gains access to a centralized platform that aggregates data from various sources, including production machines, IoT sensors, and quality control systems. Here’s how leveraging AI for data management benefits the company:

- Analyzes historical equipment performance data and identifies patterns indicative of potential equipment failures. The company receives automated alerts notifications of impending maintenance issues, allowing it to proactively schedule maintenance activities before critical failures occur. As a result, downtime is reduced, and production efficiency is optimized.

- The company gains insights into quality control metrics in real-time. The AI system detects anomalies in production processes and product quality. By addressing quality issues early on, the company reduces the risk of costly defects.

- AI-powered data management also facilitates production optimization. It helps analyze production data and demand forecasts and recommends optimal production schedules and resource allocations. The company uses these insights to adjust production levels in response to changing demand patterns.

Why Use Informatica

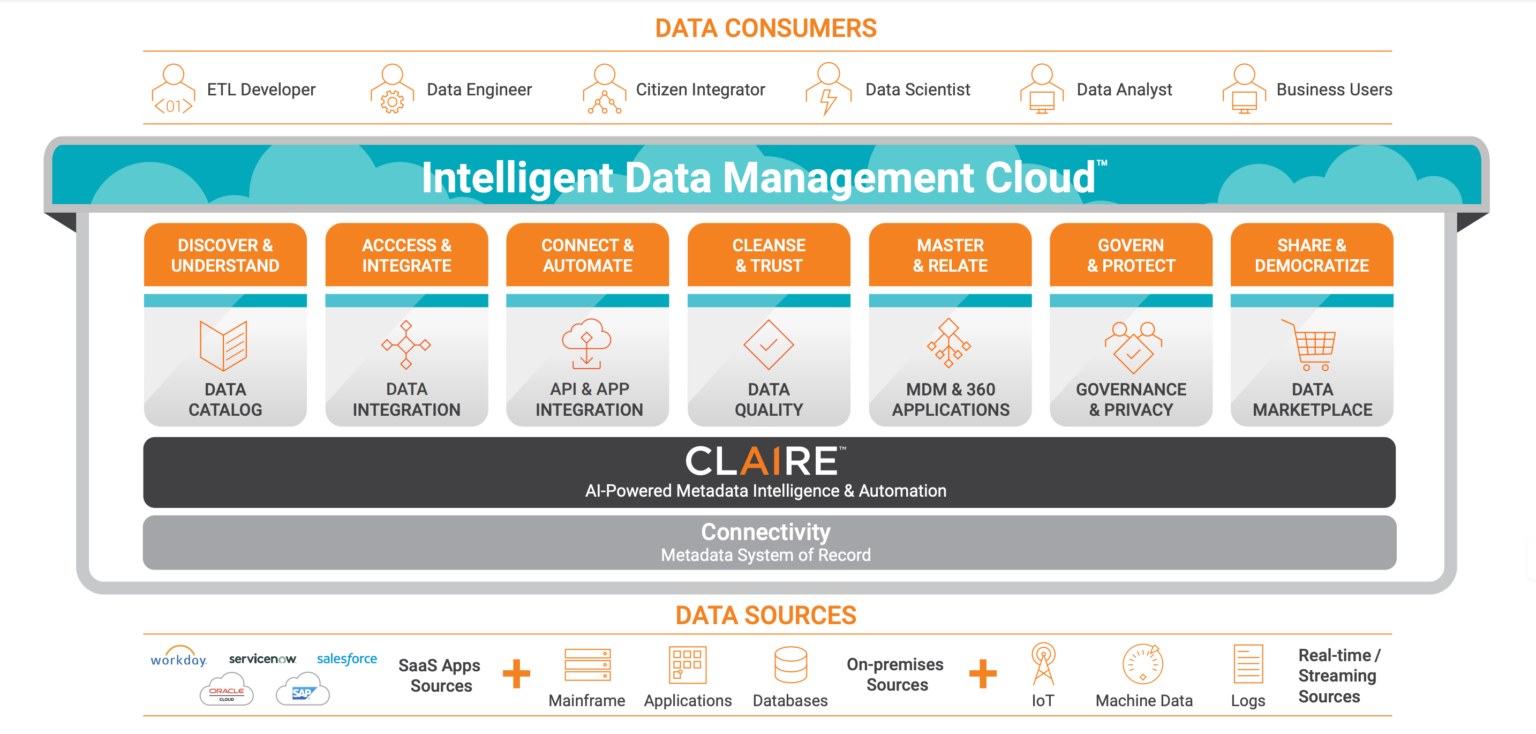

Image Source: Informatica

Here are some key reasons to leverage Informatica for your manufacturing business:

Smart Supplier Management

Informatica offers a compelling solution by automating operational processes and streamlining workflows such as supplier onboarding. This minimizes manual intervention and drives cost efficiencies. Additionally, Informatica’s platform enhances organizational agility and accelerates time-to-market by automating supplier verification, qualification, and onboarding processes through a centralized management portal.

You can swiftly onboard suppliers, facilitate faster product launches, and enhance competitiveness in dynamic markets. Furthermore, Informatica’s Intelligent Data Management Cloud optimizes supplier spend by providing comprehensive insights into total spend per supplier. This way, you can negotiate more favorable discounts, pricing, and terms, and drive down procurement costs and improve overall financial performance.

Optimized Supply Chain

Today’s globalized business landscape demands a robust and diversified supplier network. How do you quickly identify reliable alternative suppliers for specific needs in any region? Enter Informatica! The intelligent platform provides you with AI-driven insights, and you gain visibility into your supplier network’s health status.

This allows for proactive identification of potential risks, enabling informed action to mitigate disruptions and ensure supply chain continuity. Informatica’s trusted, centralized platform like Supplier 360 provides a single source of truth for supplier information. It helps facilitate stronger relationships and improve supplier collaboration.

Compliant Supplier Ecosystem

Informatica’s intelligent platform centralizes supplier and product data into a single source of truth. This solidifies transparency and facilitates adherence to local and international compliance regulations. This streamlined approach minimizes the risk of errors and inconsistencies.

You can ensure that your business operates within the legal and ethical frameworks of diverse markets. Also, in today’s world, environmental, social, and governance concerns are increasingly critical within the supply chain. Informatica embeds ESG targets into standardized supplier onboarding and management workflows. You can ensure your suppliers align with your organization’s commitment to sustainability and ethical practices.

Derive Maximum Business Value from Informatica Products with LumenData

Leverage Informatica’s full potential with LumenData’s expertise. As a Platinum Partner, we deliver proven solutions to enable data transformation for your business. Our customizable MDM & governance framework, packed with industry best practices and accelerators, ensures a perfect fit for your unique needs. Check out our SaaS extension for Supplier 360.

Get in touch to learn more about our solutions.

Authors

Shalu Santvana

Content Crafter

Mohd Imran

Senior Consultant